A Healthcare System Built on Disposability

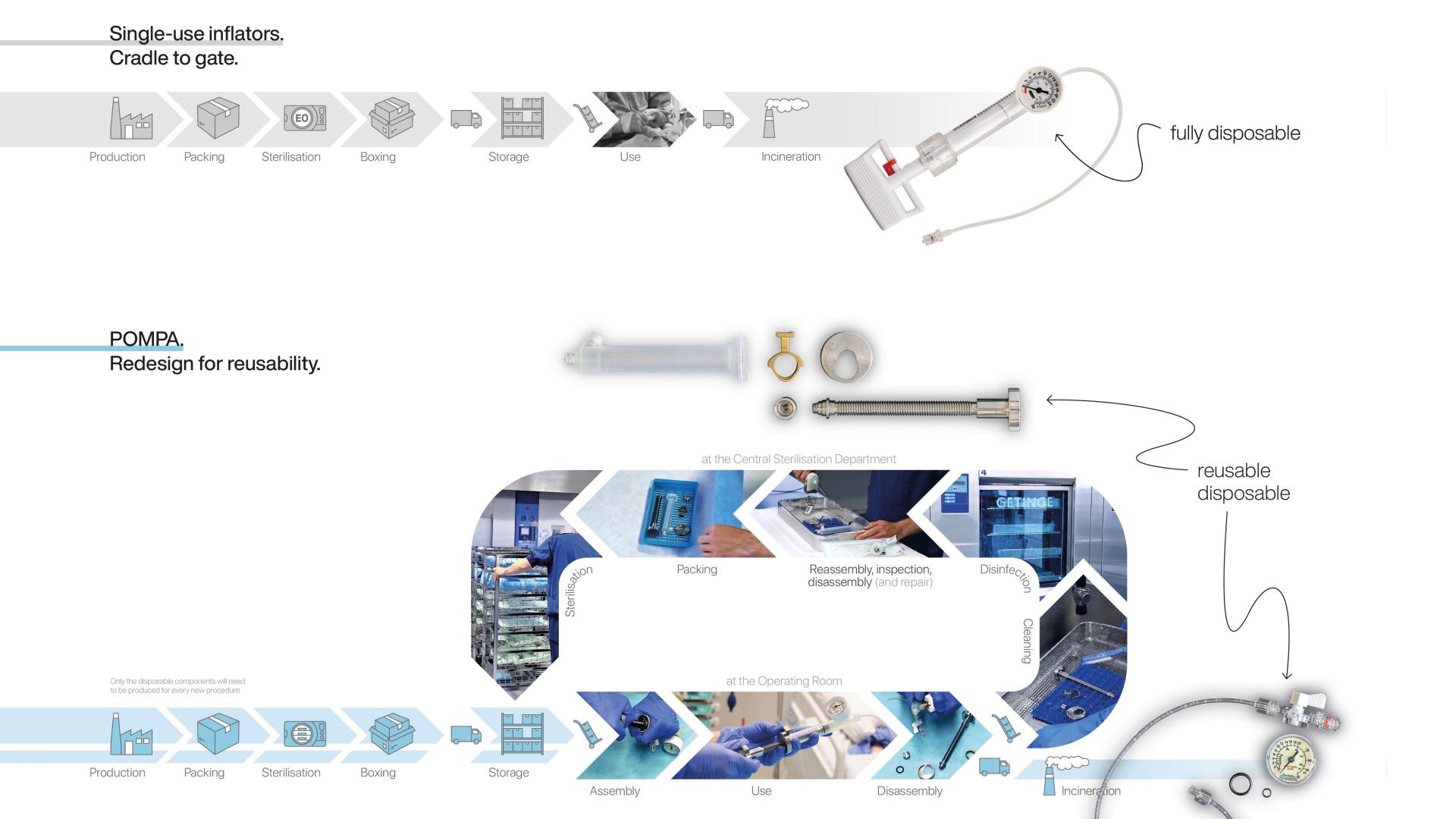

The Dutch healthcare sector accounts for 7% of the country's national carbon emissions and 13% of material consumption. Single-use medical devices contribute significantly to this burden. Inflators are a major example. They are essential in interventional cardiology and radiology to restore blood flow to blocked blood vessels. They must withstand 25 times more pressure than standard car tires.

Each year in the Netherlands, approximately 100,000 inflators are used once and then incinerated. After use, they are considered contaminated and need to be disassembled, cleaned, and sterilised for reuse. However, current inflator designs are not made to be taken apart, making reuse technically impossible and keeping hospitals dependent on single-use devices.

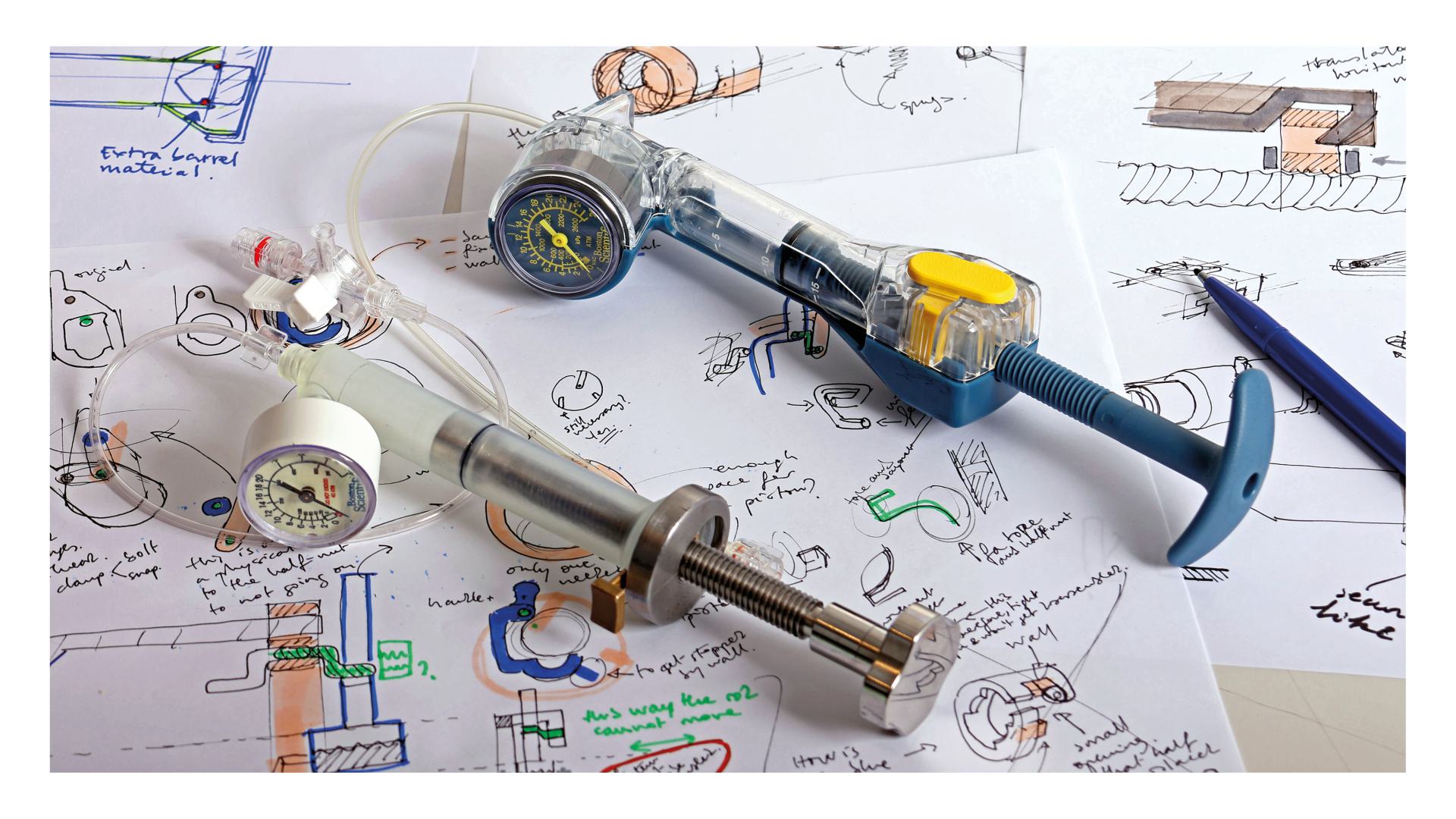

POMPA. Shifting from Disposable to Reusable

POMPA leads the shift from single-use to reusable medical devices to achieve a more sustainable healthcare sector. It is the first non-single-use inflator, the first that can be disassembled without breaking, and the first that allows reuse within hospitals by adapting into current decontamination workflows.

It has a lower environmental and economic impact than current inflators after only nine uses, and its reusable components can be reused for up to 1,000 procedures, significantly reducing waste and material consumption.

Implementing Reusability Within the Healthcare System

Like current inflators, POMPA allows for both rapid and precise balloon inflation and deflation movements. It does so through an innovative quick-release mechanism. This new mechanism is intuitive for doctors, guarantees clinical performance, and enables disassembly, making decontamination and safe reuse possible.

Its reusable components integrate into hospital decontamination workflows and withstand the high-pressure use and sterilisation cycles. All of the reusable components are made of stainless steel 316L except for the transparent barrel, which uses PEI to ensure there are no air bubbles or blood within the fluid, and the nitinol spring mechanism, which has already been CE-certified in reusable medical devices.

After use, POMPA is easily disassembled in the operating room. Disposable parts are discarded, while the most valuable parts, which are designed for reuse, are brought to the hospital’s sterilisation department. There, they are cleaned, disinfected, assembled, inspected, disassembled, packed, and steam sterilised. During the next procedure in the Operating Room, POMPA is completely reassembled with new disposable parts.

Free wifi available

Free wifi available

Toilets available

Toilets available

Fully wheelchair accessible

Fully wheelchair accessible

Wheelchair friendly toilet available

Wheelchair friendly toilet available