Towards a New Technology

Mass production has made products affordable and widely accessible. But it has also led us to accept an aesthetic shaped by standardized materials. Natural resources are forced into rigid, angular templates to meet the demands of industrial manufacturing. What if technology adapted to natural materials, instead of the other way around?

Wrapping Waste explores exactly that logic. Intelligent algorithms are used to recognize the potential in irregular materials and leftover pieces. Leather offcuts serve here as a case study:

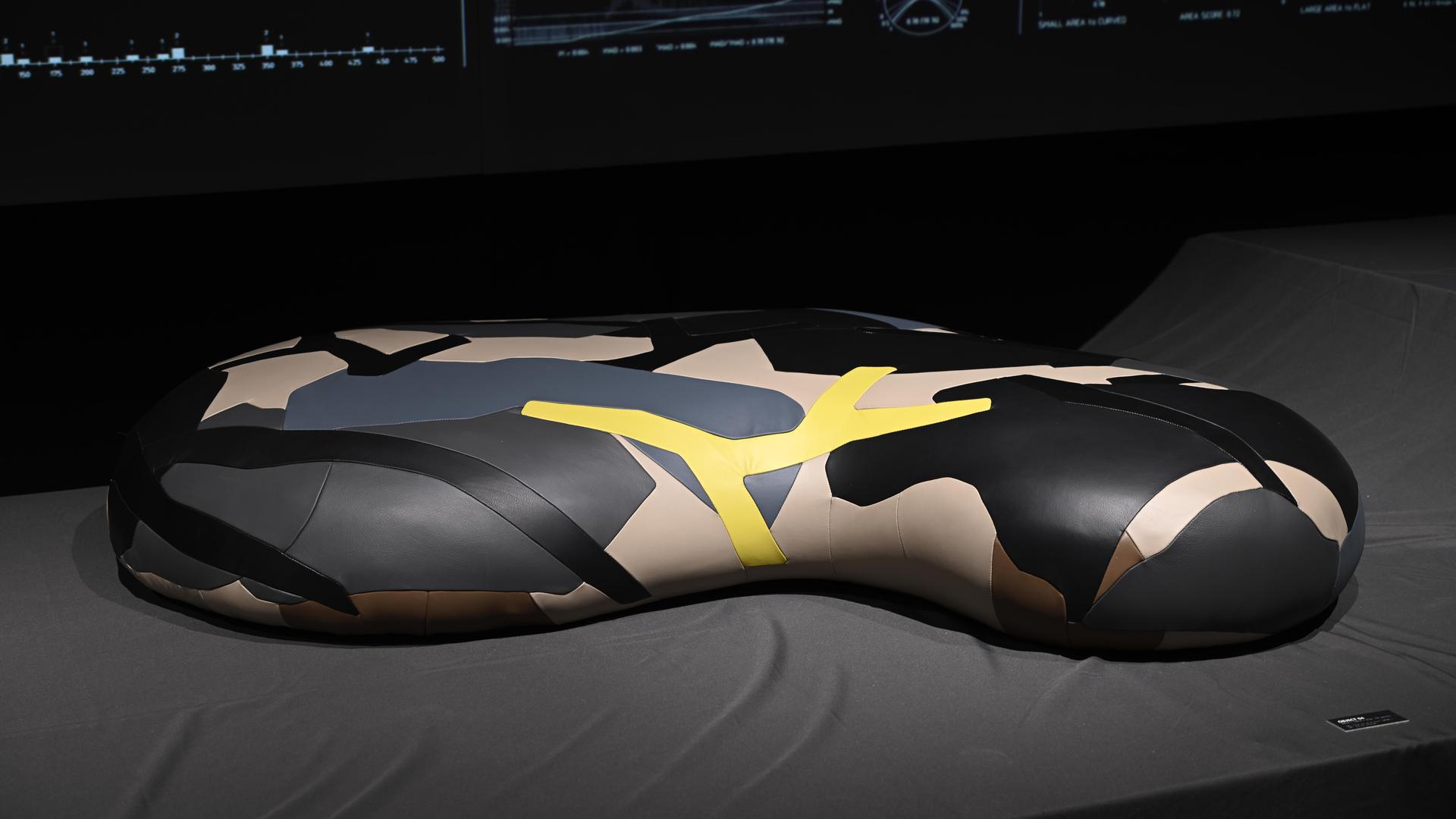

A sequence of programs that map the entire process — from scanning the leather pieces, to designing the furniture, to generating the patchwork cover. In this last step, irregular pieces are arranged to wrap the surface in the most efficient way possible.

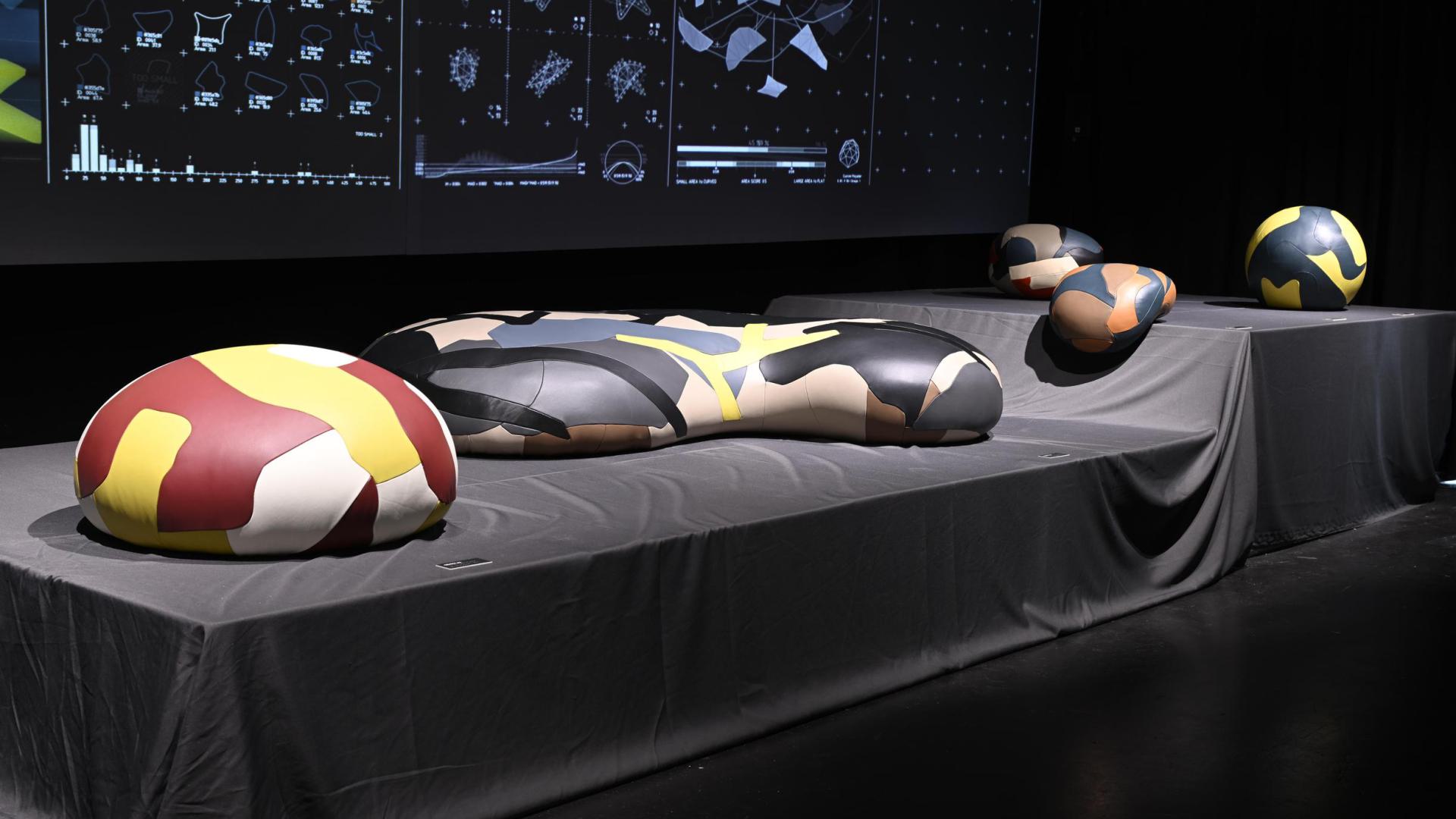

Using these design tools, I created a series of upholstered furniture from leather waste, sewn with an industrial sewing machine and filled with leftover upholstery foam. All the leather was generously sponsored by the Italian furniture brand MOROSO.

The Digital Factory: How it Works

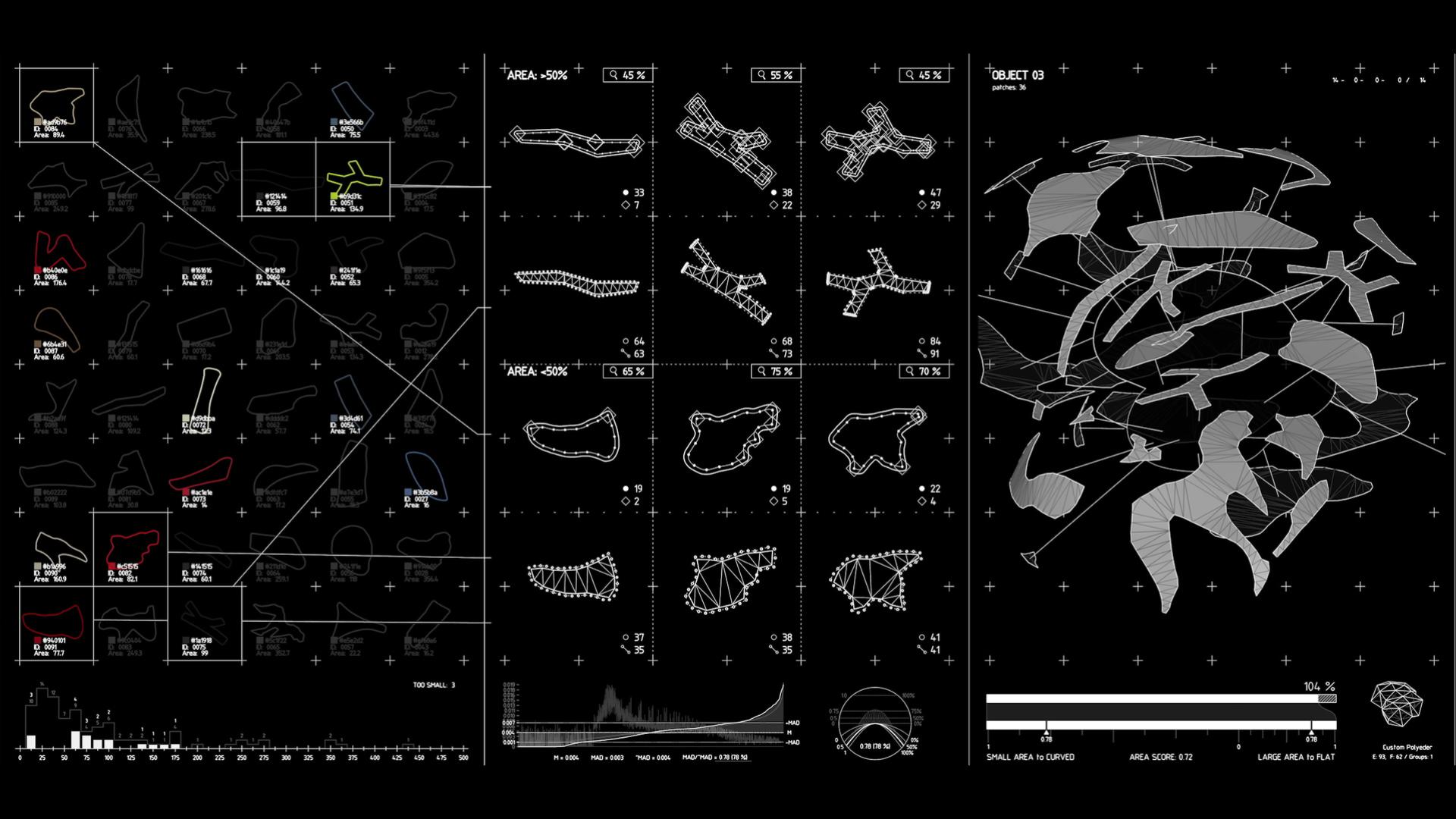

The core software requires a variety of intelligent tasks to transform digitally flat leather pieces into an efficient, balanced distribution across the complex surface of a design object. An animation illustrates the digital workflow.

It begins with a rough plan that follows a preset design guideline and iteratively refines it, adding increasing levels of detail and accuracy. With each step, the cover gradually emerges, and even slight changes in parameters can result in a completely different outcome.

Simplified process steps:

• Sort & Quantify - leather pieces are selected based on their surface area

• Analyze & Arrange- frameworks of leather pieces are positioned near the design object

• Wrap & Interact - frameworks are wrapped onto design object while interacting with others

• Refine & Prioritize – original pieces are restored at their final position and ranked by user settings

• Trim & Unroll - pieces are trimmed by others according to priority, and resulting pieces are flattened into sewing patterns

Every step operates in an iterative environment, aiming to use the pieces and their shapes as efficiently as possible. The system enables up to 96% material use.

Looking Ahead!

Each year, around 4.4 billion square meters of leather hides are produced globally, with approximately 1.1 billion square meters flowing into furniture manufacturing. Typically, about 45% of this is discarded as offcut—almost half a billion square meters. This is where algorithms can intervene, repurposing the waste before it is shredded or incorporated into other materials.

But leather is just one example — billions of square meters of similar material are discarded daily and could be revalued using similar technologies. Yet for any successful result, a well-designed product and precise configuration of parameters are essential. That’s why in the end, the role of the designer remains irreplaceable.

Toilets available

Toilets available

Partially wheelchair accessible

Partially wheelchair accessible