The originally Dutch company Fokker Elmo is one of the world leaders in the development and production of electrical cabling in aircraft and aircraft engines. Most of the assembly work is still done manually, as production series are relatively low and specifications may vary from customer to customer. Fokker Elmo sees an important role for computerisation in the future of the company, but also has to deal with the aviation world’s very strict safety regulations, which often require great patience prior to innovation being accepted.

The complete computerisation of the manufacturing process is not yet economically or technically feasible, but Fokker Elmo is already taking steps to develop the factory of the future. For example, Fokker Elmo is currently developing an MES system (Manufacturing Execution System), which will digitise many of the current work instructions. Constructing a strong interface between this digital data flow of instructions and the shop floor operators could already be an important step towards full computerisation in the future. This interface between the digitally prepared work orders and shop floor operators is intended to ensure that employees can work more efficiently and comfortably while avoiding manufacturing production errors.

About Fokker Elmo

Fokker Elmo is the result of a hundred years of continuous invention and innovation in the field of aircraft technology. The present company originated from the former Fokker Aircraft, which was founded at the beginning of the 20th century by the Dutch aircraft pioneer Anthony Fokker (1890 - 1939). In 1996 Fokker Elmo was acquired by Stork and currently operates within the GKN group, a major player in the field of aerospace innovation. The company’s great strength and current market position are partly due to its loyal employees, many of whom have worked for Fokker for a long time and their great passion for the company, its customers and its products.

As part of GKN, Fokker Elmo is specialized in Electrical Wiring Interconnection Systems (EWIS): making the cabling for aircraft and helicopter parts for both the commercial and the military market. Fokker Elmo is the number 2 worldwide in EWIS and works for well-known customers like Airbus, Boeing, Bombardier, Rolls-Royce, Pratt & Whitney, Northrop Grumman and Lockheed Martin.

Fokker Elmo has an outstanding reputation in the market and has several locations around the world (in the Netherlands, Turkey, China, USA, Canada and India), with a total of around 2200 employees.

The shop floor operators’ working environment

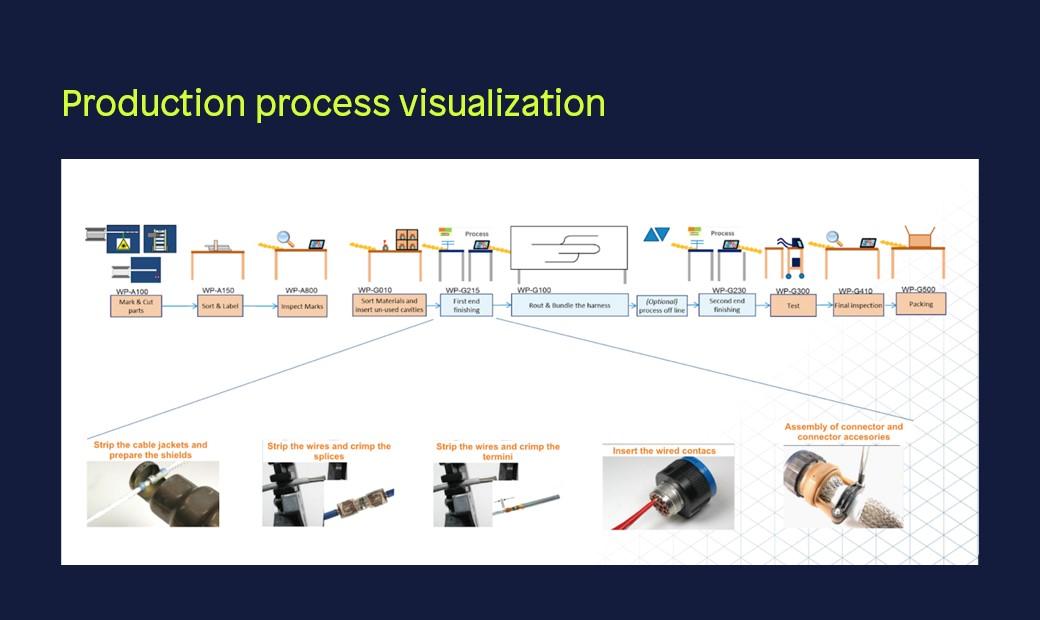

A shop floor operator is a Fokker Elmo employee who assembles cable systems to the customer's unique specifications. To facilitate this, all cables are individually marked, laid out in the correct form for installation, often (partially) insulated and connected to specified connectors and plugs. This is a very labour-intensive, still largely manual and at the same time data-driven process. To assemble the cable systems, the shop floor operator has to constantly switch between different operations and reference materials: the tools, digital manuals, instructions on paper, different codes on the cables, and connectors. Inspections must also be performed and recorded following each step. A large volume of instructions is available for each cable system. Engineers at Fokker Elmo design the systems in close cooperation with the customer and meticulously flesh out the requirements, the corresponding list of components and assembly instructions in a specially developed digital environment. The sources from which the shop floor operators retrieve instructions are sometimes physical, sometimes digital, sometimes difficult to read, have different layouts, formats and forms and are not always close to the workplace. In order to perform the tasks properly, the employee sometimes has to refer to different sources dozens of times for each connector: from instructions on paper to those on screen to the tool, while constantly searching for the right cable or correct opening in the connector based on the finely printed codes. The correct execution of the instructions during assembly is essential, as any errors will only come to light when the finished product is tested and must then be sought. Any damage to materials used as a result of incorrectly performed work can also lead to delays and additional costs. Properly executed assembly work avoids costly time loss during or at the end of the process. The designers selected for this What if Lab will be given a tour and have a workshop at their disposal during the masterclass to experience for themselves how a shop floor operator works. It is important to realise that production in the Netherlands is not identical to that in Turkey or China. In addition to cultural differences and the approach to work, production capacity and final products are different at each location.

The design challenge

This What if Lab challenge is to improve the interface for the shop floor operator. Although many of the operators are very experienced in their work, the workflow is not always equally efficient. Manual production is time-consuming, which is why Fokker Elmo strives for solutions to optimize manual work - which is unavoidable for the time being - as far as possible. Digitisation and data streams will play an important role here.

An interface is in fact a link between two systems: it transfers information from one system to another. In this case, (digital) instruction data is first sent to the shop floor operator, who employs it to construct the necessary wiring harnesses configuration. How can shop floor operators benefit as much as possible from the (digital) data that is available to simplify their work, making it more pleasant and improving efficiency with fewer mistakes? And can the work planners also learn from data that is collected during the work? In brief, can we strengthen the link between the source of the data and its user by designing a user-friendly interface for the shop floor operator?

As described under the previous heading: the current 'interface' consists of various sources of information that all have to be read differently. This depends heavily on the eyes and fine motor skills of the hands alternating between different actions. When compared to a car’s interface, for example, the user seems to be more versatile: the pedals, the steering wheel, various buttons on the dashboard, the handbrake, gearshift and the route navigation system can be used simultaneously and thus ensure that the driver can drive efficiently and safely.

The second part of the question embodied in this assignment is how this interface could be physically integrated into the workplace and workflow for the shop floor operators. So we are not only looking for ideas for the dashboard, but also for solutions in both the digital and the physical environment: a 'cockpit' that supports shop floor operators with different tools to navigate efficiently through the different activities.

For shop floor operators at Fokker Elmo, everything is currently based on good eye-hand coordination, but perhaps there are other senses or body parts that could be used more effectively? Could physical aids make the work more intuitive? Could a visualisation of data on or in the workplace support the work? Is there a way to make codes on the leads and connectors more legible? Could digital tools be devised to serve as a tool for operators for validating tasks more efficiently and more comprehensibly than the current manually stamped paper documents? In brief, how can we improve the cockpit and interface for the operators now and in the future?

Naturally the masterclass will be an important source of information: an opportunity to work with shop floor operators, to gain hands-on experience of tasks. Employees involved on a daily basis improving and implementing the digital work environment at Fokker Elmo will also provide extra explanations to form the basis for getting started with this assignment.

Who are we looking for?

The main purpose of this assignment is to creatively discover what is possible for a new interface. Empathy with the operators and their work is vital. However, the distance that an 'outsider' automatically has when they look at a situation can be very valuable in providing new insights and opening the door to possible solutions. Fokker Elmo employees are sometimes so caught up in their daily work that it becomes difficult to consider things from a conceptual level and see possibilities instead of obstacles. Designers with a degree of technical insight would be at a great advantage for this What if Lab. Of course, Fokker Elmo has enormous in-house technical expertise that can be supplemented here. To supplement these competencies we are looking for designers who are strong conceptual and creative thinkers and able to make these ideas visual.

This What if lab is looking for concepts for tools to improve efficiency for shop floor operators and to make their environment more user-friendly. Following a first presentation of the concepts in April, Fokker Elmo will assess if the concepts or parts of them justify further development. The concepts selected will be developed further by the studios in collaboration with Fokker Elmo into visual prototypes. (By this we mean that the designs will be fleshed out as (3D) visualizations, models or mock-ups, but we do not expect that the underlying technology, programming or actual products will yet exist.) If Fokker Elmo decides to continue to develop these visual prototypes after the presentation in June 2019, new terms will be agreed between the designer and Fokker Elmo, and the parties will continue their collaboration outside the scope of the What if Lab.

The objective of the What if Lab is to initiate an open collaboration in which both parties can exchange and utilize each other’s knowledge and skills. For this reason, meetings will take place regularly during this period, so that developments can be supported by the organisation and linked to developments that are already taking place within the company or innovations that are already being tested. It is also sensible to regularly align expectations and to check from a pragmatic perspective if the practical feasibility of a concept can still be guaranteed. This is to ensure that we work towards a product that Fokker Elmo can actually implement in the future.

Design criteria

The manufacture of Electrical Wiring Interconnection Systems (EWIS) for aircraft and helicopters has to meet very strict requirements and regulations. In addition, Fokker Elmo has a lot of variables to deal with in producing the final results and the data streams for each individual product are huge. To ensure maximum practical effectiveness, the design should take the following criteria into account:

- Besides the large volume of data, the manner in which the work instructions are supplied is extremely diverse. This is true in terms of content and medium (sometimes on paper, sometimes on screen). In addition, it cannot always be universally labelled, which does nothing to help consistency.

- A project is currently running to implement a Manufacturing Execution System, which will increase the level of digitalisation on the shop floor. Data, work instructions will be stored here and in due course a shop floor operator will be able to retrieve them with a single click.

- Every action performed by a shop floor operator must be traceable (who did it and when, and who checked it and when). This is a non-negotiable demand from the industry and the customer.

- Fokker Elmo factories are distributed throughout the world: in the Netherlands (Hoogerheide), Turkey (Izmir), India and China (Langfang). These four different cultures each have their own specific requirements for the shop floor or an interface.

Registration and participation conditions

Registering for What if Lab: the factory of the future can be done through this link.

We do not need you to provide a design for this What if Lab yet, but would you please upload your brief motivation (max. 600 words) and a condensed portfolio (2-5 relevant projects).

Before registering, please remember to read the Terms and Conditions of Participation. Upon registration you automatically agree to the terms and conditions as described in this attached document 'Terms and conditions of participation WILFokker Elmo'.

Remuneration

The three selected participants will each receive an amount of €750 for the hours they will spend participating in the masterclass and the course/workshop given by the shop floor operators at Fokker Elmo. This masterclass with corresponding workshop will take place on the 26th of February 2019 at Fokker Elmo in Hoogerheide and will last all day.

In addition, participants will each receive an amount of €2,500 for the development of a concept and the corresponding intermediate meetings and a presentation on the 10th of April 2019. The participant(s) selected below to develop the concept into a design with an elaborate visualisation (for example in a model, 3D animation, drawing or video) will receive a fee of € 7,500. This remuneration is to compensate for the hours worked.

IP and confidentiality obligations

The intellectual property rights ("IP") and copyrights of the concept designs not selected by the jury for further development on 10/04 2019 will remain entirely with the participants. Fokker Elmo is only granted the right of use for non-commercial purposes (e.g. publicity purposes), which may be used after informing the relevant Participant. The name of the creator must always be stated.

Fokker Elmo is entitled to use the intellectual property rights from the concepts selected for further development within the scope of the What if Lab, free of charge. As a result of this transfer, Fokker Elmo has unlimited rights to exploit the design, without any compensation other than the remuneration for participation in the What if Lab. However, Fokker Elmo is obliged, if it decides to continue to develop the design after What if Lab, first and foremost to enter into exclusive discussions with the designer in question in order to investigate whether the designer could and would like to develop it further.

Selected designers will be asked to enter an Non-disclosure agreement with Fokker Elmo. This NDA has been drafted in cooperation with Dutch Design Foundation.

An extended version of the conditions regarding IP can be found in the Terms and Conditions of Participation.

Programme design

After the deadline for registration (10-02-2019) has passed, the registrations will be transferred to Fokker Elmo. In consultation with DDF, three design studios will be selected to work in this What if Lab. They will be invited to participate in a masterclass and workshop at Fokker Elmo, after which they will independently develop a concept for the subsequent six weeks. Progress interviews will be planned with Fokker Elmo to discuss headway, criteria, expectations and check practical feasibility.

The designers will present the final concepts to a jury comprising Fokker Elmo employees. Based on these presentations and the contact during the project, they will decide on whether Fokker Elmo would like to continue to develop one or more of the concepts within the What if Lab. If this proves to be the case, another period of ten weeks will follow for the designer(s) concerned, in which the concept will be fleshed out with a number of intermediate meetings and tests taking place. A working prototype is likely too ambitious a goal, but an extensive visualization is expected that shows the follow-up research subsequent to the concept phase. This visualization is open to free interpretation (e.g. model, 3D animation, drawing or video). This result will be presented to Fokker Elmo on the 20th of June 2019.

Timeline

| Deadline for applications | 10-02-2019 |

| Announcement of selection | 14-02-2019 |

| Masterclass for the selected designers | 26-02-2019 (location: Fokker Elmo, Hoogerheide) |

| Update meeting 1 | 14-03-2019 (location: Fokker Elmo, Hoogerheide) |

| Update meeting 2 | 28-03-2019 (possibly via Skype) |

| Presentation concepts and selection | 10-04-2019 (location: Dutch Design Foundation) |

| Update meeting 1 | 18-04-2019 (possibly via Skype) |

| Test 2 | 02-05-2019 (location: Fokker Elmo, Hoogerheide) |

| Update meeting 2 | 14-05-2019 (possibly via Skype) |

| Test 2 | 28-05-2019 (location: Fokker Elmo, Hoogerheide) |

| Presentation prototype | 18/20-06-2018 (Location: Fokker Elmo, Hoogerheide) |

Throughout the process, in the weeks that no update meetings are planned, there will be a fixed time (day/hour) every week for telephone contact between Fokker Elmo and the designers/studios to get feedback on decisions and fine-tune the process.

Questions?

If you have any questions about this What if Lab, please contact the programme manager Dries van Wagenberg via dries@dutchdesignfoundation.com.